MBI Nano and Microfabrication Core

The µFabrication Core provides a spectrum of design and microfabrication services to our internal researchers, R&D partners, and external clients. Our team of engineers and researcher have over 40 years of accumulated knowledge and hands-on experience.

Microfabrication Core helps with the design and fabrication of innovative devices to further our understanding of cells.

Our in-house capabilities cover the entire micro-fabrication chain, including:

- Micro-patterns design

- Optical masks fabrication

- Lithography (with or without alignment)

- Pattern transfer (Si dry/wet etching, film deposition and lift-off)

- Surface functionalization

- PDMS soft lithography and microfluidics

We also have available highly specialized technologies such as EBL and nano-imprinting through collaboration with other facilities and industry partners, both locally and overseas.

Additionally, we offer micro-structure characterizations via optical and SEM imaging, step profile measurement, and thickness and refractive index measurement.

We also offer prototyping by 3D printing (thermoplastic polymers and UV-curing resins) and small scale CNC machining (for plastic or soft metal).

Available Facilities

The µFabrication Core is located within an ISO7 class clean room (at NUS’ T-lab) with a yellow light ISO6 class inner zone, dedicated to UV lithography.

Currently, our equipment consists of:

- Heidelberg DWL66 fs, laser writer for mask writing, with gray scale and direct writing capabilities

- MJB4 SUSS MicroTec Mask aligner with Deep UV option

- CEE Spin coater

- Prazitherm Hot Plates (photo resist baking)

- Kloè UV-KUB UV-LED flood and mask exposure box (for 4” substrate)

- Samco 10NR-RIE plasma etching system, equipped with CF4, SF6, Ar and O2

- Sentech 500Si ICP deep silicon plasma etcher, equipped with CF4, SF6, CHF3, C4F8, Ar and O2 capable of Bosch-type processes

- AJA e-gun and thermal evaporator (Au, Cr, Ti and Cu)

- Diener Pico plasma tool (300 W max power, O2 and Ar)

- Vacuum oven

- Solvents wet bench

- Acid wet bench

- Bruker Dektak Contact Profiler

- Optical microscope (Olympus)

Non clean-room-based equipment includes:

- SEM (JEOL JSM 6010LV)

- Reflectometer (Thetametris FR-pRo with Miniaturized Spectrometer in 370-1000 nm range and 5x, 20x and 50x objectives)

- VO29 Memmert Vacuum Oven/Degasser

- Laurel Spin-coater (for PDMS)

- Harrick plasma cleaner (with O2)

- Tergeo dual chamber plasma cleaner (with O2)

- Kloè UV-KUB UV-LED flood exposure box (up to 9” substrate)

- Ultimaker 3, FDS 3D printer

- Formlabs Form 3 SLA 3D printer

- Charly 4U CNC machining tool (plastic or soft metal)

In-house Facilities

µFabrication Core Intranet [MBI staff only]

Application examples

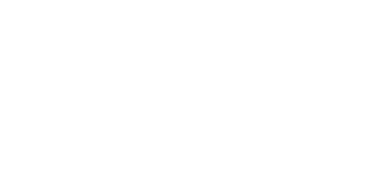

At the µFabrication Core, we help with the design and fabrication of micro-systems used to study biological systems from a physical and mechanical perspective.

Our focus lies, but is not limited to, topological features; geometrical stamps for protein stamping; pillars and cantilevers for force sensing, as well as microfluidic and micro-optical systems for cell experiments.

Some of the ongoing projects at MBI are:

- Micro/nano pillars

- Geometrical patterns for protein stamping (PDMS stamping; UV stamping)

- Microwells

- Micro fluidic devices

- Surface topography (Diffuser lithography; Thermal reflow; Gray scale lithography)

- soSPIM

MBI’s µFabrication Core helps with the design and fabrication of innovative devices to further our understanding of cells.

Submit Request or Inquiry

External

External users may submit an inquiry to Mohammed Ashraf at mbima@nus.edu.sg

Internal

Internal users may submit a project request to the µFabrication Core by accessing openfreezer.mbi.nus.edu.sg [MBI staff only].

Location

mbi.nus.edu.sg

mbi@nus.edu.sg

+65 6872 6123

Mechanobiology Institute, NUS

Level 5 T-Lab

National University of Singapore

5A Engineering Drive 1

Singapore 117411

Gianluca GRENCI

Research Assistant Professor, Facility Manager

mbigg@nus.edu.sg

mbi.nus.edu.sg/gianluca-grenci

Mohammed ASHRAF

Microfabrication, cleanroom management

mbima@nus.edu.sg

MONA Suryana

Research Associate, Nano-imprinting

mbimona@nus.edu.sg

Jegan SHANMUGARAJAH

Research Assistant, Microfabrication, Technical service

mbijvs@nus.edu.sg

Saburnisha Binte Mohamad RAFFI

Research Assistant

mbismr@nus.edu.sg

FOO Sebastian Junwei

Research Assistant, Microfabrication Engineer

foojw@nus.edu.sg